Building an Isolation Boat - V10 Sailing Dinghy

Background and Introduction

As a third year medical student in 2020, during coronavirus / COVID19 I was suddenly stuck with limited surgery study (only via Zoom) as all elective surgery was suspended. Finding myself with a lot of free time on my hands, I started building a boat with Ian, my three year old son! He was surprisingly helpful, loved drilling holes with me (pulling the trigger as I held the drill), inserting zip-ties, and loved painting.

This page is a log of the build of the V10 (sailing version) from Bateau / BoatBuilderCentral.

You can click on an image to open the gallery and step through the images and see all of the captions.

Contents

- Early April 2020 - Choosing What to Build and Buying Supplies

- 16th April 2020 - Drawing up onto plywood, cutting, and turning 8' of plywood into a 10' boat - Butt joins

- 17th April 2020 - Stitching together

- 18st April 2020 - Epoxy and Fibreglass

- 19st April 2020 - Coating with Epoxy

- 23rd April 2020 - Fitting the Interior

- 25th April 2020 - Terrifying Holes

- 29th April - Fibreglassing and Fairing

- 5th May 2020 - Painting In Closed Compartments

- 7th May 2020 - Fibreglassing in the Seats

- 13th May 2020 - Painting Proper

- 21st May 2020 - First Top Coat

- 30th May 2020 - Procuring A Sailing Rig and Looking Like a Boat

- 4th June 2020 - Antipenultimate post: Nearly Finished Painting

- 12th June 2020 - Penultimate post: A Completed Boat and Rowboat Launch

- 19th June 2020 - Naming and Sailing Launch Day

Build Log of the V10 Sailing Dinghy

Early April 2020 - Choosing What to Build and Buying Supplies

Starting with plans purchased from Bateau. It's reasonably challenging for a non-engineer to blow up A4 diagrams to 8' x 4' plywood (I didn't want to wait for international shipping for full-size plans), but the instructional guides on the site on how to do this (and most facets of the build) are very well written - once you find them (they're separate to the plans).

Having built the boat, I think the plans are good and easily worth the ~$40. They're well-written, clear, nearly always at what I felt was an appropriate level of detail, and generally a breeze to use. I'd definitely buy another set of plans from Bateau / BoatBuilder Central. Assuming that I'm reading it correctly, there are some minor errors and omissions (the daggerboard is not the right size for the daggerboard slot), vague descriptions of knees and conflicting information from the designer on the forum "just use the plans" vs the plans saying "measure from your boat". That said, these are pretty trivial and shouldn't stop you buying.

The only real issue that you should be aware with the plans (in my opinion) is that the bill of materials (BoM) is all over the place for accuracy. I had substantially more fibreglass tape than required, more epoxy than required, and nowhere near enough filler (not for the boat and certainly not for the amount of epoxy recommended - and I made sure to coat all timber and not miss any steps - I double-checked). The BoM also underestimates the timber required as it doesn't appear to take into account things like the rubrails, transom plate, and sailing pieces. It's a "if you half-arse the boat and build it to the minimum, you'll need to buy at least this much timber, but you'll have heaps of glue" BoM!

The other criticism that I think is fair is that the estimated time to build is rather fictional, unless I suppose, you're a professional boat builder, it's your 73rd boat, you're not building optional sailing parts of the boat, and you're finishing it to a workboat (rough-as-guts) standard. This opinion seems pretty much shared on the forums, which are an excellent source. Still, it's lots of fun, and I would get these plans and do it again, no questions.

16th April 2020 - Drawing up onto plywood, cutting, and turning 8' of plywood into a 10' boat - Butt joins

Lots of cutting of plywood sheets. I suppose it's a bit like sewing with power tools. I'd recommend a circular saw if you have a decent one, you'll get much neater straight lines.

17th April 2020 - Stitching together

Fun with zip-ties. Some people suggest using copper wire, but honestly, zip ties are miles easier. Just go buy a big lot of them for cheap.

18st April 2020 - Epoxy and Fibreglass

Isla is pleased with the boat progress. Bottom seams are all filled and fibreglassed, and the bottom hull sealed with epoxy. Next step will be to coat the inside and measure up for the seats, daggerboard case and front deck. Fiberglass tape is going on - goes surprisingly transparent (from white) if you’ve never seen it used before.

An aside for the glue nerds (I’m sure there’s some here): I’m using west system 105 with the slow 206 hardener, and it still goes off like a bomb when you mix in thickener to make a filleting or fairing compound. Brisbane weather isn’t great for epoxy, so you have to make quite a few small batches as you go.

19st April 2020 - Coating with Epoxy

Not much progress today as can be seen by the deep dark emptiness in Monty’s eyes.

The inside has now been sealed as well. Once this dries I can get my table back to start cutting out the seats, foredeck, and centreboard.

23rd April 2020 - Fitting the Interior

Making progress on the fiddly bits - middle seat (marking and cutting those curves was painful) and laminating the daggerboard case together as I couldn’t easily obtain the right side timber. It’ll be wrapped in fiberglass so it’ll be pretty tough by the time it’s finished.

Ian wanted to hop in as soon as we got home from daycare! “I will sit here, and Mummy will sit here and Monty next to me and Daddy can sit over there and row”.

25th April 2020 - Terrifying Holes

Finished the scary part - cutting a big hole in the bottom of the boat for the daggerboard case. It fit, and is now firmly in place with epoxy and layers of fiberglass.

The skeg (helps the boat track straight when rowing) is also installed on the bottom (yet to be glassed) as are pads to screw on the rowlocks.

Next steps are: cut some holes for hatches, add some more glass to the bottom once the top of the daggerboard case has dried, and then finally install the seats!

29th April - Fibreglassing and Fairing

This is a big update, but not much visual change sadly!

The rubrail/gunwales are now being epoxied on (the other side is tacked in place for symmetry but not shown). Fairing is now going on (white gunk to smooth out fibreglass edges - it’ll be sanded smooth tomorrow).

More holes cut in the boat for hatches, and the bottom fibreglass applied to the skeg and daggerboard box.

Ian took some more photos today (you can tell by the perspective).

5th May 2020 - Painting In Closed Compartments

Now onto painting! Seats are finally sorted (see the hole for the daggerboard in the middle seat). I’ve just painted the inside of the buoyancy compartments for now so that I can put on the tops and fibreglass them in.

Inside and outside has been faired and sanded (looks messy but is very smooth). Sorry neighbours, I highly recommend Ryobi cordless random orbital sanders.

Also, the rubrail has been finished and the prow and transom had a rough shape by hand. Various bits and pieces have been routed to have nice rounded edges, and the top of the sides has had the ply routed flush with the rubrail using a flush bit.

I’m using norglass shipshape high build primer which is the worst smelling thing I’ve ever encountered. It’s also got more air in the packaging than a packet of chips (I know it’s sold volumetrically but still...) Worst part is that it also dissolves plastic cups and foam rollers. West systems epoxy is better in every way to work with.

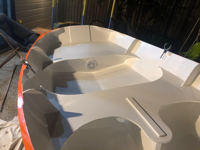

7th May 2020 - Fibreglassing in the Seats

Seats are fibreglassed in! My textbooks still didn’t need to be opened though! 😉 Now it’s just finishing off with some knees (curved decorative bits to stiffen the transom-side joints), figuring out how to step a mast, more fairing and painting, and then just attaching hardware.

Scale model was created by Sarah so that Ian could design the colour scheme - which happens to be inspired by a children’s YouTube star called Blippi. I think it came out surprisingly tasteful actually! (The model is slightly different as it’s the rowing not sailing version so doesn’t have a foredeck).

13th May 2020 - Painting Proper

Finally some massively visible progress - painting has started! It’s proving slightly challenging to thin the paint enough, but we’re getting there.

Inside isn’t painted yet but will come. I highly recommend 3M respirators (if all the geriatrics I see wearing them haven’t bought them all out for their COVID shopping expeditions), available at your local hammerbarn.

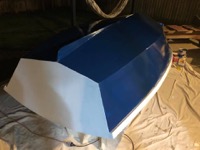

21st May 2020 - First Top Coat

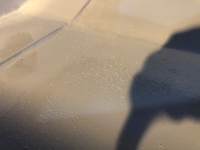

And now we’ve just started to add some colour! Unfortunately the weather hasn’t been very cooperative, and with 4-6 coats (let’s face it, 6) required on both top and bottom (ie 12 days minimum), this is taking a while.

The colour scheme is Ian’s (shown in a previous post). A range of bits and bobs (rudder, centreboard, tiller) are also in various stages of progress. It’s going a bit slow because “Honey, I’d really love a full woodworking workshop including a thicknesser and bandsaw” was assumed to be a facetious comment.

I’ve got to help out with farm work this weekend, so things will be a bit slow for the next update. Sorry that the quarantine boat updates will be slower!

30th May 2020 - Procuring A Sailing Rig and Looking Like a Boat

Finally nearing completion. 4 coats of paint still to go (one more orange, one more blue, two white). Would be finished by now except I had to go mark cattle.

The mast and sail have been procured from some old mismatched windsurfing gear, and it’ll be a cat-rigged dinghy with a pull over windsurfing sail because that’s super easy to rig and go. Still have to pick up some cleats and a block and rope today.

4th June 2020 - Antipenultimate post: Nearly Finished Painting

As exams draw near and (more importantly) my boat launch deadline (uni break) draws near, we’re possibly up to the antipenultimate isolation boat post. The second coat of orange paint is down, and the first interior white paint. One more white coat inside to go (with nonslip additive for the floor). Then after that is hardened, we’ll flip it and put the last blue coat on.

The tiller has been made out of a scrap bit of timber, and the rudder and daggerboard are now being painted after a correction to it as the plans appear to be wrong. All the bits and bobs (blocks, cleats, ropes, other thingies with weird names) have been obtained. It should be simple to sail with a main sheet, downhaul, and outhaul only.

Ian has been getting stuck into the painting with me and is doing a pretty good job!

12th June 2020 - Finished and Rowing Launch!

The penultimate post - finish and launch day for rowing! The final update will be the naming of the boat and the first sail.

We had a lovely family day out, and Ian was very excited to launch his "Blippi Boat". He had a row with his grandfather 'Geppy' as well and had a lovely day. Performance wise, the boat rows very well and easily. It's a stable little boat and easily rowed with myself, Ian, and Geppy with freeboard to spare.

19th June 2020 - Naming and Sailing Launch!

The final post - launch day for sailing and a name!

Although we intended to sail with my family, COVID stopped this as I was unable to go and visit them interstate. Instead, we had a family day out on Wivenhoe Dam. We named the boat, "Sequestration". A pun on isolation, and sea quest (yes, groan). $12.85 plus shipping for the name in vinyl stickers.

Ian insisted on being on the tiller, and managed pretty well to follow simple instructions of "push it away", and "pull it towards you". He needed to be encouraged to stay on a straight line though as he enjoyed being in control and making the boat respond. He pretty much was on the tiller the whole way out and back including through quite a few tacks and a couple of gybes.

It sailed reasonably well with its oversized (5m2 windsurfing sail vs 3m2 gaff rig on the plan). The balance is a bit out compared to the usual bigger boats I was sailing pre-COVID – I could reasonably easily overpower the rudder and daggerboard and effectively change our heading by adjusting the mainsheet, but it was still eminently (and easily) sailable, even with a 3yo on-board!

So, now what? I've been banned from building aircraft and hovercraft as my argument of "safety didn't put men on the moon or climb Everest" didn't stick. Instead, I've discovered a slightly more insane option: The Class Globe 5.80. Build your own boat, then race it around the world, solo or double-handed. Plans came out this month, and the race is in 2024. As the timing is perfect, it must be fate... 😃